GS to Speak on Silicone Rubber for Flexible Electronics MP Solution at Flex Conference

Materials Innovation for Commercialization of Flexible Hybrid Electronics

Hsinchu, Taiwan, February 18, 2021 - General Silicones (GS), a steering committee member for flexible electronics at SEMI Taiwan, is announcing it will share innovations in silicone material for flexible electronics manufacturing at the Flex 2021 Virtual Conference on February 23.

The presentation will be held during the session of Flexible Materials & Technology From Asia at 4:30 PM Pacific Standard Time (PST) by Dr. Anupam Mukherjee, Technical Director at the R&D Center of General Silicones.

Making Green Silicone Rubber Mass Production Friendly

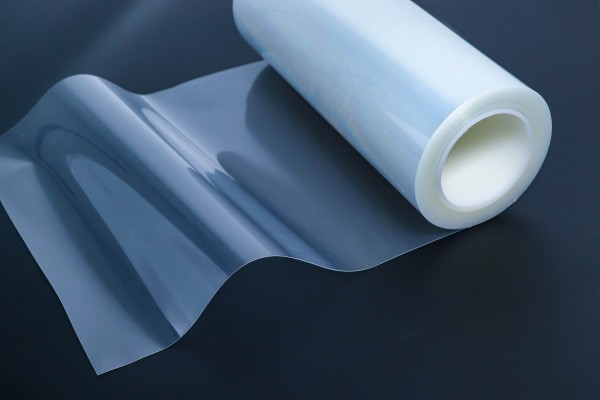

Silicone rubber is a well-known environmentally friendly material with many chemical and physical properties that would make it ideal for flexible electronics. But the low wettability of cured silicone rubber excluded silicone so far as a material from broader usage in flexible hybrid electronics (FHE) design and manufacturing. Until now, companies have had no choice to use the outstanding elastomeric properties of silicone in the mainstream of FHE, only limited in advanced academic research using only liquid PDMS for prototyping. Realizing this innovation gap, GS is offering a sustainable industrial solution of printable silicone film for high volume production of wearable, e-skin, and stretchable electronics.

Need Gap Analysis

With an experience of over 50 years, considering a huge gap between the industry and academia about the use of silicone materials in flexible hybrid electronics, GS developed Compo-SiL® focusing the following issues:

* A silicone based printable film with tunable mechanical and elastic properties that can support the academia and the upcoming flexible hybrid electronics supply chain and speed up the development of FHE.

* Along with printability, silicone films must provide laminability to other surfaces for encapsulation purposes. Also, these printable and laminable films should have the capability to bind with textile for wearable electronics industry applications.

* Dr. Anupam Mukherjee will be sharing how the GS R&D Center overcame this surface energy enhancement of silicone problem and now creates silicone rubber sheets with ultra-thin modified PU layers. To cover a wide range of applications, there is a need of roll-to-roll printable silicone film for the flexible hybrid electronics market. Compo-SiL® films are broadly separated into these categories:

* Printable & Wearable Film

Having silicone along with a printable and laminable modified layer available in large scale roll-to-roll process opens the scope of designer clothing and fashion technology. The printable wearable film allows for building up flexible circuits by inkjet printing, screen printing etc. As all raw materials used are high grade and non-toxic, harmful impact on the environment is prevented.

* Printable E-skin Film

As silicone is a bio-friendly and sustainable material, silicone-based printable films are the best candidates for e-skin industry. They are well suited for the healthcare industry as well as wearable electronics due to the low mechanical stiffness comparable to the human skin.

Based on the 50 years of experience in manufacturing silicone products, all Compo-SiL® rubber sheets/films are manufactured to be printable, laminable and wearable to textile and e-skin.

For more information on the presentation, visit

About General Silicones

General Silicones (GS) was founded in 1970 in Taipei, Taiwan, and is now represented worldwide – including Europe, China, Japan, and South-East Asian countries. GS is a major distributor of silicone materials and an active silicone products manufacturer with ISO 9001, IATF 16949, and ISO 14001 certifications. The company has manufacturing plants in Hsinchu, Taiwan; Wujiang, China; and Bac Giang, Vietnam. With decades of experience in this field, GS has the ability and capacity to provide a wide range of silicone products for many industries, including medical, automobile, consumer products, electronics, and IT. GS listed on Taiwan's Emerging Stock Market in 2011 (TPEx: 4730). For more information about GS, please visit www.generalsilicones.com. For more information on Compo-SiL®, please visit www.compo-sil.com.

Media Contact:

GlobalPR Taiwan PR Agency

Kayla Lee

kayla@globalpr.agency

+886-2-2882-5577